記事見出し

A traditional method of ink production passed down through generations.

There are two main types of ink: “oil smoke ink,” made from burning rapeseed oil, sesame oil, or paulownia oil, and collecting the soot, and “pine smoke ink,” made by burning pine resin. Recently, there are also inks made from mineral soot.

Among these, “oil smoke ink” is known for its fine particles, deep black color, and strong gloss, representing high-quality ink. Oil smoke ink originated during the Muromachi period at Todaiji Temple’s Nikadai Hall, where soot collected from the temple’s lamps was mixed with glue to create ink.

In our garden, we continue to preserve high-quality oil smoke ink using the secret techniques passed down through generations.

1.Soot Collection:

Pure vegetable oil is placed in earthenware pots, and a wick is lit to produce soot, which is then collected. To ensure even accumulation of soot, all pots are moved every 20 minutes.

2.Gelatin Dissolution:

Gelatin made from animal bones or skin is placed in a double boiler and heated for an extended period to create a gelatin solution.

3.Wooden Molds:

Wooden molds for ink, made from pear wood, are intricately carved with characters and patterns. Each mold holds about 15g of ink, but approximately 25g of wet ink is poured into it due to drying shrinkage.

4.Molding:

A mixture of soot, gelatin solution, and fragrance is taken out, kneaded by hand until it shines, and then carefully molded into the ink molds.

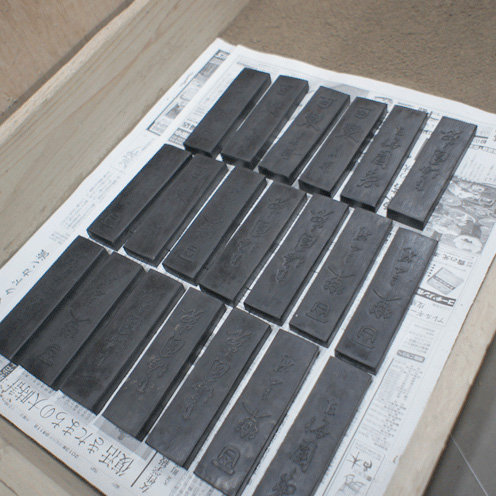

5.Ash Drying

The ink removed from the molds is buried in wood ash with high moisture content on the first day, and then gradually replaced with wood ash with less moisture from the second day onwards. This ash drying process continues for about one week for small-sized items and around 30 to 40 days for larger ones.

6.Natural Drying

After the ash drying process, the ink (with approximately 70% of its moisture removed) is hung from the ceiling indoors by weaving it with straw for natural drying. This process usually takes about two weeks to three months.

7.Finishing and Polishing

Once the natural drying is complete, any ash or other substances adhering to the surface of the ink are washed off with water, one piece at a time. After washing, a finishing agent is applied to the surface for makeup. Additionally, depending on the product, the surface may be softened by roasting over charcoal and polished thoroughly with clam shells to bring out the gloss.

8.Coloring Finishing

The polished ink is left to air dry for about three days to a week (to remove any moisture retained from washing), then colored using gold powder, silver powder, or other pigments.